The goals of energy conservation, environmental protection, and consumer convenience are being addressed today with the development of state-of-the-art, energy-efficient materials. This includes expandable polystyrene (EPS), which is basically ... air contained inside thin-walled polymer beads.

EPS is one of the most popular insulation products on the global market. It is a gas-filled material of expanded plastic class made from polymers that are produced entirely in Russia. The grade of EPS used in construction for the insulation of exterior walls is PPS 16F. By virtue of antipyrene additives, it is non-combustible, while the structures built with EPS are non-flammable. The benefits of EPS include high energy efficiency as well as low water and vapor permeability. It can be used to insulate buildings during all seasons of the year and in any weather conditions, include extreme ones. At the same time, EPS is lightweight and does not require special pre-treatment prior to installation.

EPS is immune to fungus and microorganisms, in addition to being biologically inert and very durable: according to the findings of the testing lab at the R&D Institute of Structural Physics, EPS panels “have successfully passed the temperature-humidity cycling tests resulting in service life predictions of 80 years in multi-layered walls exposed to temperatures ranging within ± 40°С”. All this contributes to the broad applications of EPS as a thermal insulation material, even in underground and buried structures.

THE BENEFITS OF EPS INCLUDE HIGH ENERGY EFFICIENCY, AS WELL AS LOW WATER AND VAPOR PERMEABILITY

Multiple opportunities

The main consumer of EPS is the construction industry: the product is used to thermally insulate roofs, exterior walls, walls below ground level, foundations, walls of basements and buried structures, and balconies. According to market research, EPS accounts for 11% of the insulation materials market in Russia. It is also used in industrial construction to thermally insulate roads. In harsh climates, the freezing and heaving of soil can cause asphalt pavement deterioration and railroad safety hazards. EPS panels provide added insulation capacity for road pavement and even extend the service life of the road. A layer of EPS in the pavement protects the road from temperature extremes, mitigates deformation, and makes it more resistant to seismic shifts, which makes the product particularly relevant for earthquake-intense places like Japan.

ACCORDING TO MARKET RESEARCH, IN RUSSIA, EPS ACCOUNTS FOR 11% OF THE INSULATION MATERIAL MARKET IN RUSSIA

In 2010, SIBUR pioneered EPS production in Russia in response to growing demand for the material, driven in part by the state-supported Affordable Housing programme, whose overhaul activities included improving the thermal performance of buildings. The company’s second production line was launched in 2012, and by January 2022, the Perm-based SIBUR-KhimProm had already produced one million tonnes of EPS under the Alphapor trademark. Over the course of 12 years, SIBUR-KhimProm won the Russia-wide Top 100 Russian Goods competition with the “Best Industrial Product” in 2012, 2015 and 2017.

The range of SIBUR’s products includes EPS blocks for embankments in road construction, where this polymer product is capable of replacing conventional sand. The use of EPS helps to reduce transportation costs, improve soil-bearing capacity, eliminate the use of steel piles, reduce the settlement duration and extent, and even tackle vehicle pollution.

AS OF JANUARY 2022, THE PERM-BASED SIBUR-KHIMPROM HAS ALREADY PRODUCED ONE MILLION TONNES OF EPS UNDER THE ALPHAPOR TRADEMARK

Other uses of EPS include thermal insulation in oil, gas and product pipelines, trunk and lateral pipelines, water intake and treatment systems and heating lines, as well as the production of insulated containers, furniture, combat helmets and even pieces of art.

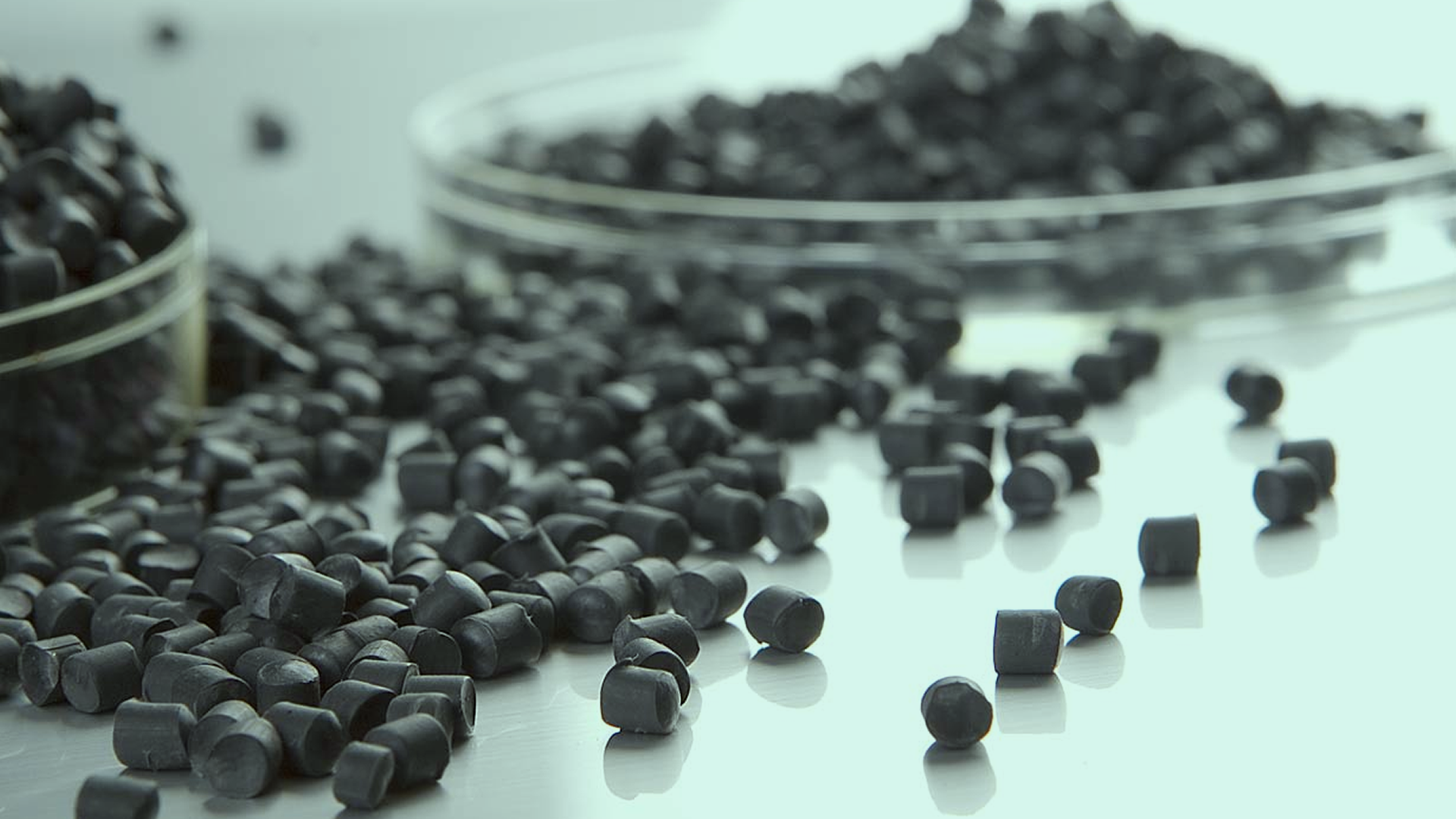

EPS is produced in granules that are expanded with pentane, a harmless, natural-gas condensate that is injected under precise temperatures. The granules are resilient and are fused together using steam. The resulting material is a lightweight, rigid and cellular plastic containing 98% air.

Beginning in 2021, SIBUR-KhimProm has been using special flame retardants in EPS production: an antipyrene for polymers developed by SIBUR’s scientific centre and included by the Federal Service for Intellectual Property (Rospatent) in the Top 10 Russian Inventions of 2020. This helped make EPS insulation non-combustible and only capable of melting when it is exposed to an open flame.

Improved energy efficiency

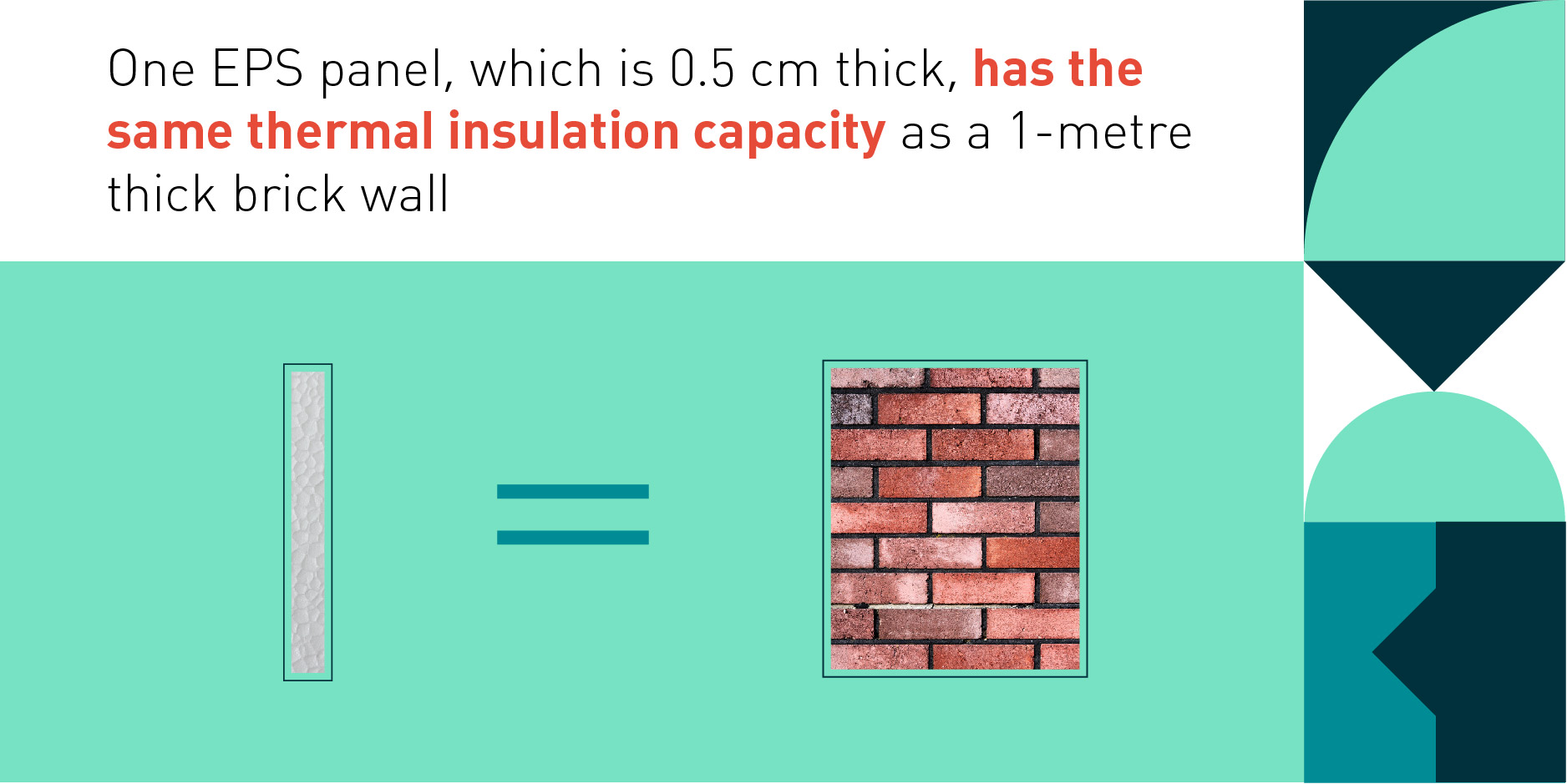

EPS insulation in exterior walls helps reduce energy loss by 70% and heating costs by 3.5 times. Heating accounts for ca. 20% of total power consumption in Russia: according to the Construction Materials Department of the Moscow State University of Civil Engineering, this requires an equivalent of 240 Mt of fuel.

Reduced СО2 emissions

EPS insulation in exterior walls helps reduce greenhouse gas emissions from energy consumption by 70%. Meanwhile, buildings contribute 17.5% of energy-related emissions.

Environmental outperformance

After only one year of use in exterior walls, an EPS panel outweighs the environmental impact of its production and logistics by a factor of 10. And throughout the EPS life cycle, the environmental effect outweighs the impact from production, logistics, installation, deinstallation and disposal by 250 times.

As an innovative material for insulation, EPS is convenient, efficient and environmentally friendly.

Comments (0)